Types of Snubbers used in the nuclear industry.

In the nuclear industry, snubbers are primarily used in piping systems, reactor coolant loops, and structural supports to absorb shocks, vibrations, and dynamic loads caused by seismic events, thermal expansion, and operational transients. The two main types of snubbers used in nuclear power plants are:

- Mechanical Snubbers

These snubbers function through mechanical components that restrict movement during sudden dynamic loads while allowing free movement under normal conditions.

Types of Mechanical Snubbers:

- Friction Snubbers:

- Use frictional resistance to absorb energy during shocks or rapid movements.

- Common in seismic applications.

- Viscoelastic Snubbers:

- Use rubber or polymer-based materials to dampen vibrations and absorb energy.

- Effective in reducing both shock loads and continuous vibrations.

- Hydraulic-Activated Mechanical Snubbers:

- A hybrid system where a hydraulic mechanism triggers a mechanical locking device.

- Provides high-load resistance during dynamic events.

- Hydraulic Snubbers

These use fluid-based damping mechanisms to control movement during high-stress conditions while allowing normal thermal expansion and contraction.

Types of Hydraulic Snubbers:

- Constant-Flow Hydraulic Snubbers:

- Allow free movement at low speeds but resist sudden movement by restricting fluid flow through an orifice.

- Used in reactor coolant systems and steam generators.

- Variable-Flow Hydraulic Snubbers:

- Adapt resistance based on the velocity of movement.

- Used in structures where varying loads need different damping levels.

- Lock-Up Hydraulic Snubbers:

- Instantly lock upon sudden acceleration, providing rigid support during events like earthquakes or pipe ruptures.

- Common in primary and secondary piping supports.

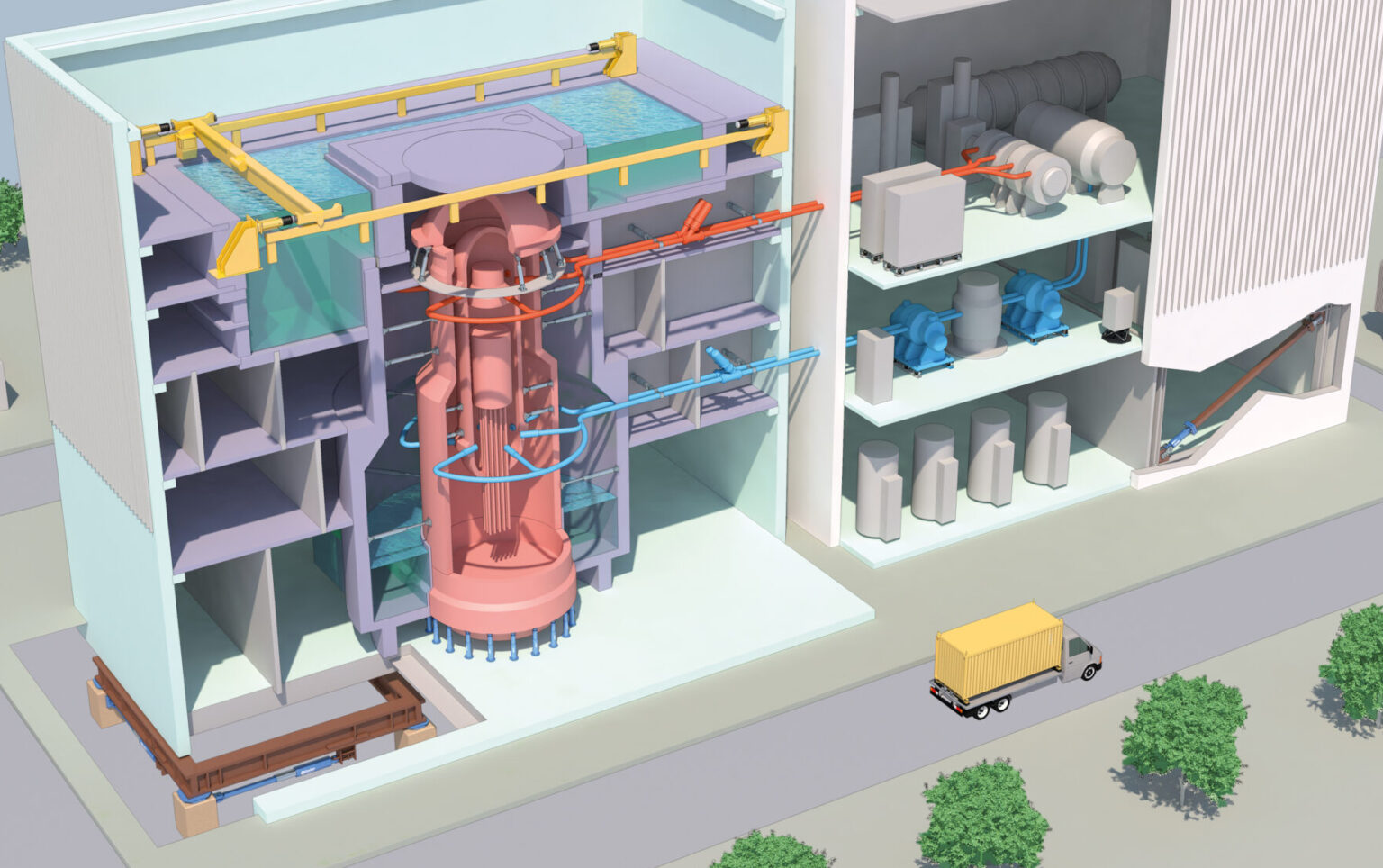

Image Source- Taylor

Please visit our Snubber Test benches for Nuclear Industry.

https://neometrixgroup.com/products/dynamic-snubber-shock-arrestor-test-facility