In defense manufacturing, structural integrity is not a specification — it is a survival requirement. Components such as bomb shells, pressure vessels, and munition casings are subjected to extreme mechanical and thermal stresses during service. Ensuring their reliability begins long before deployment, with high-pressure hydraulic testing playing a central role.

As defense standards tighten and operating pressures rise, manufacturers can no longer rely on conventional or low-pressure testing methods.

Understanding the Role of Pressure Testing in Munition Safety

Bomb shells and similar defense components must withstand:

-

High internal pressures

-

Rapid pressure transients

-

Long-term material fatigue

-

Harsh environmental conditions

Hydraulic pressure testing allows engineers to validate structural strength using incompressible fluid, making it far safer and more controllable than pneumatic testing — especially at ultra-high pressures.

This makes hydraulic testing the preferred method for proof testing, leakage validation, and deformation assessment in defense applications.

Why Ultra-High Pressure Testing Is Increasingly Required

Modern munition designs are pushing material limits to achieve:

-

Reduced weight

-

Higher performance

-

Compact geometries

As a result, test pressures now extend well beyond traditional industrial ranges. Systems capable of 1000 bar, 1500 bar, and beyond are no longer niche — they are becoming standard requirements in defense QA workflows.

Ultra-high pressure testing exposes:

-

Micro-cracks not visible under lower loads

-

Manufacturing inconsistencies

-

Weld and joint weaknesses

Identifying these issues early prevents catastrophic failure later.

Engineering Challenges at Extreme Pressures

Testing at very high hydraulic pressures introduces unique engineering challenges:

1. System Integrity

Every pipe, fitting, and valve must tolerate test pressure without becoming a failure point itself.

2. Operator Safety

Even hydraulic systems store enormous energy at high pressure. Controlled pressurization, shielding, and emergency relief systems are essential.

3. Measurement Accuracy

Pressure transducers and gauges must maintain accuracy under extreme loads to ensure valid test results.

4. Repeatability

Defense manufacturing demands consistent results across batches — not one-off tests.

These challenges require purpose-engineered testing machines, not improvised setups.

Why Manual Testing Is No Longer Sufficient

Historically, some pressure tests relied heavily on manual operation and visual inspection. At modern pressure levels, this approach introduces unacceptable risks:

-

Human exposure to pressurized components

-

Inconsistent pressure ramp rates

-

Limited data traceability

Automated or semi-automated hydraulic test systems improve:

-

Safety

-

Data reliability

-

Compliance with defense QA standards

They also support proper documentation — increasingly important for audits and lifecycle tracking.

Pressure Testing as Part of Defense Quality Assurance

High-pressure testing is not an isolated step; it forms part of a broader quality assurance ecosystem that includes:

-

Material certification

-

Dimensional inspection

-

Non-destructive testing (NDT)

-

Traceable test reporting

A robust pressure testing process directly contributes to mission reliability, personnel safety, and regulatory compliance.

Conclusion

As munition designs evolve and operating pressures increase, high-pressure hydraulic testing is no longer optional. It is a foundational requirement for defense manufacturing organizations committed to safety, performance, and compliance.

Manufacturers investing in dedicated, ultra-high-pressure testing infrastructure gain confidence not only in their products — but in their entire production process.

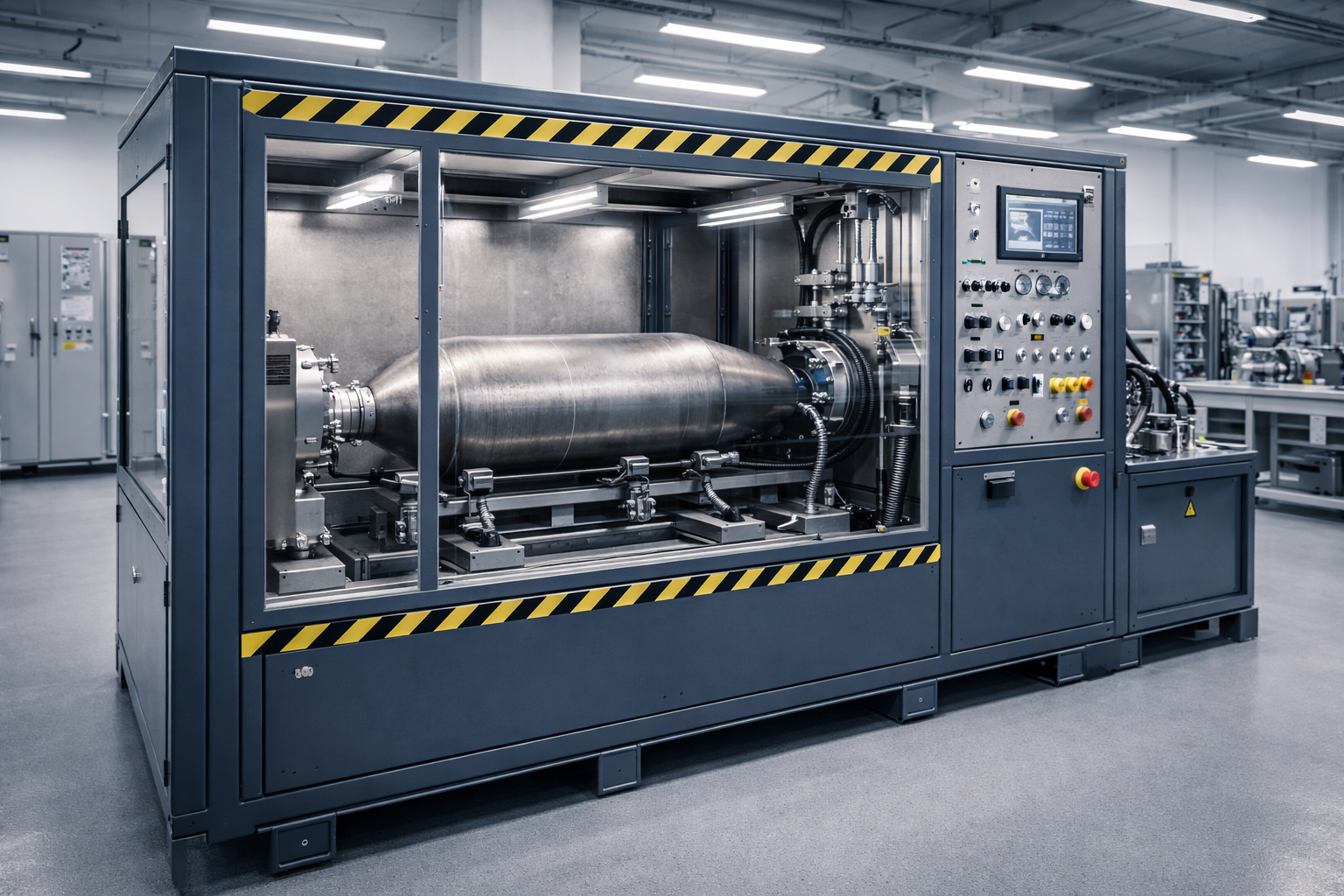

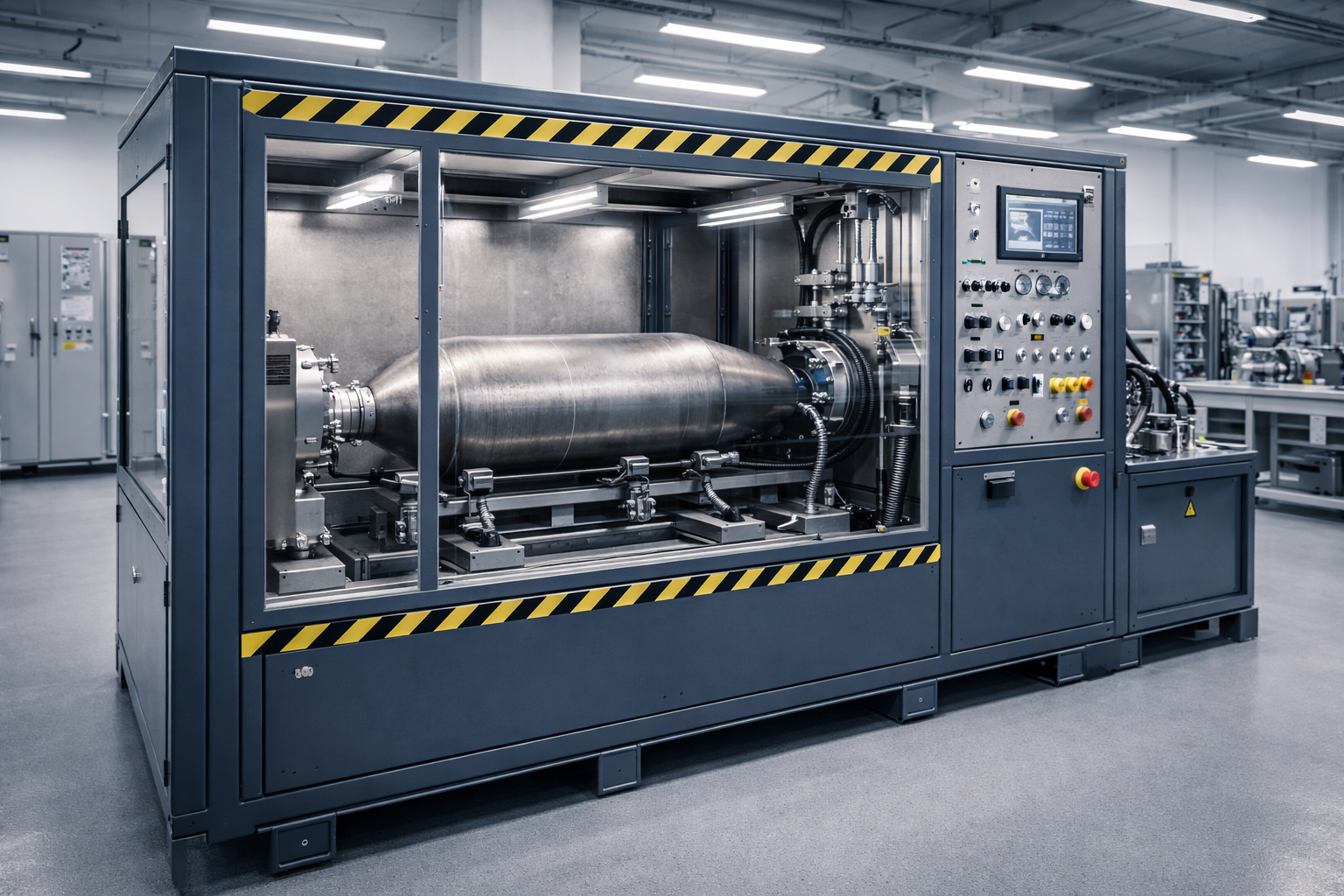

To see an example of how ultra-high-pressure hydraulic testing is implemented in a defense-grade system, explore Neometrix Group’s

👉 Bomb Shell Hydraulic Pressure Testing Machine (Up to 1800 Bar)

🔗 https://neometrixgroup.com/products/bomb-shell-hydraulic-pressure-testing-machine-upto-1800-bar