In many mechanical, piping, and structural systems, failures do not occur under steady operating conditions. They occur during short-duration events such as pressure surges, rapid valve closures, seismic disturbances, emergency shutdowns, or impact loading.

Snubbers and shock arrestors are designed specifically to protect systems during these transient events. However, their effectiveness cannot be fully evaluated using static ratings alone. Dynamic behavior plays a decisive role in how these components perform when it matters most.

Limitations of Static Testing for Dynamic Components

Static testing focuses on maximum load capacity, stroke limits, or nominal stiffness and damping values. These parameters are useful for initial sizing and basic verification, but they assume slow or predictable loading.

Real systems experience rapidly changing forces. Load application rates, acceleration profiles, and repeated shock cycles significantly influence how snubbers and shock arrestors behave. A component that meets static requirements may still respond too slowly, absorb insufficient energy, or exhibit degraded performance after repeated dynamic events.

What Dynamic Testing Evaluates

Dynamic testing applies controlled and repeatable transient loads while measuring the real-time response of the component. This allows engineers to observe how energy is absorbed during sudden events, how quickly restraint is applied, how much residual motion remains after a shock, and whether performance remains consistent over multiple cycles.

These characteristics directly affect system stability, fatigue life, and overall reliability. They cannot be inferred reliably from static data alone.

Rate-Dependent Behavior of Snubbers

Snubbers are intentionally designed to behave differently depending on the rate at which loads are applied. Slow movements, such as thermal expansion, may be allowed, while rapid movements trigger restraint.

Verifying this transition behavior is critical. Without dynamic testing, it is difficult to confirm that the snubber responds at the correct threshold, behaves consistently across repeated events, and maintains performance under worst-case transient conditions.

Importance of Repeatability in Validation

Single-event tests provide limited insight. Meaningful validation requires repeatable shock profiles so that different designs, production batches, or aging effects can be compared objectively.

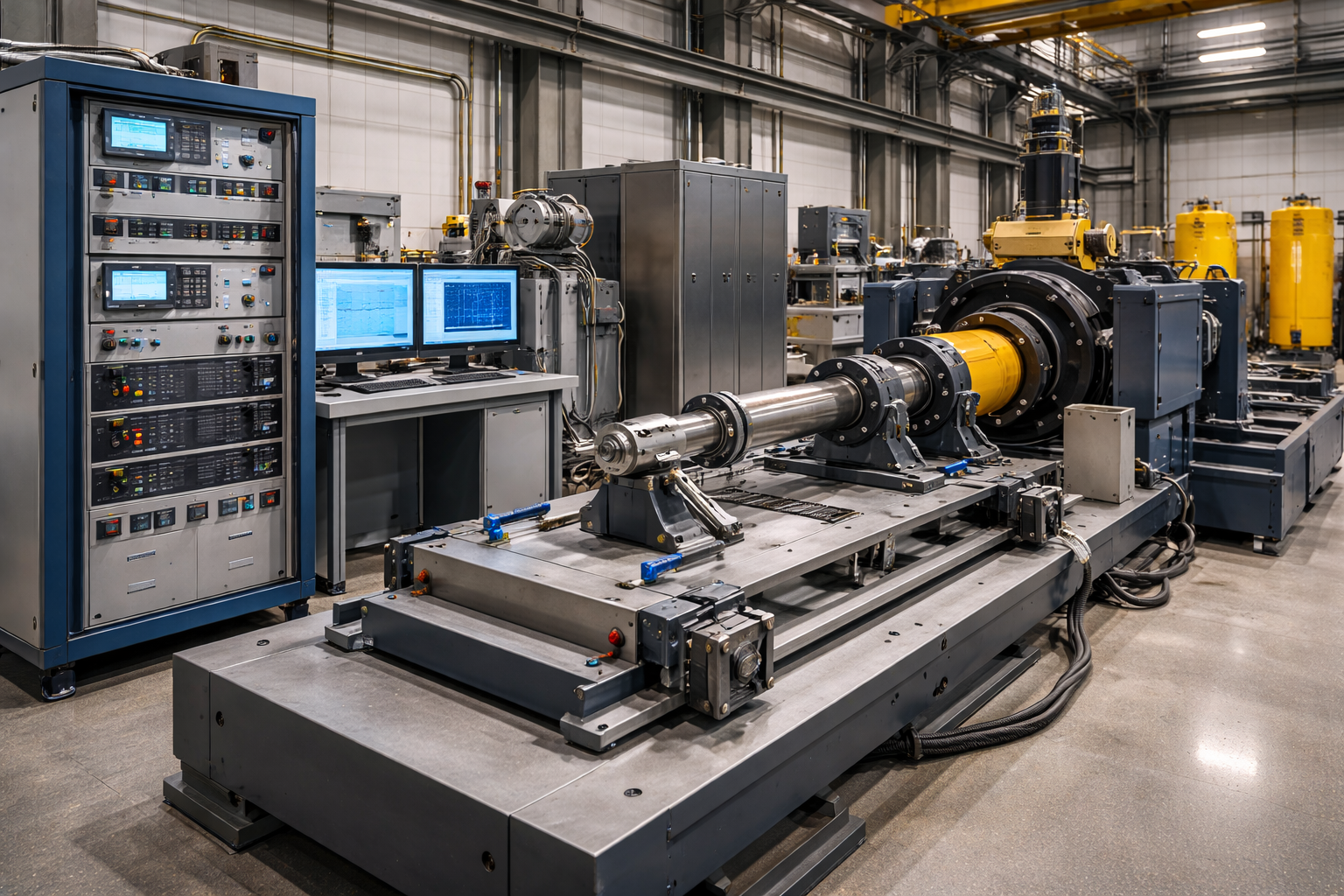

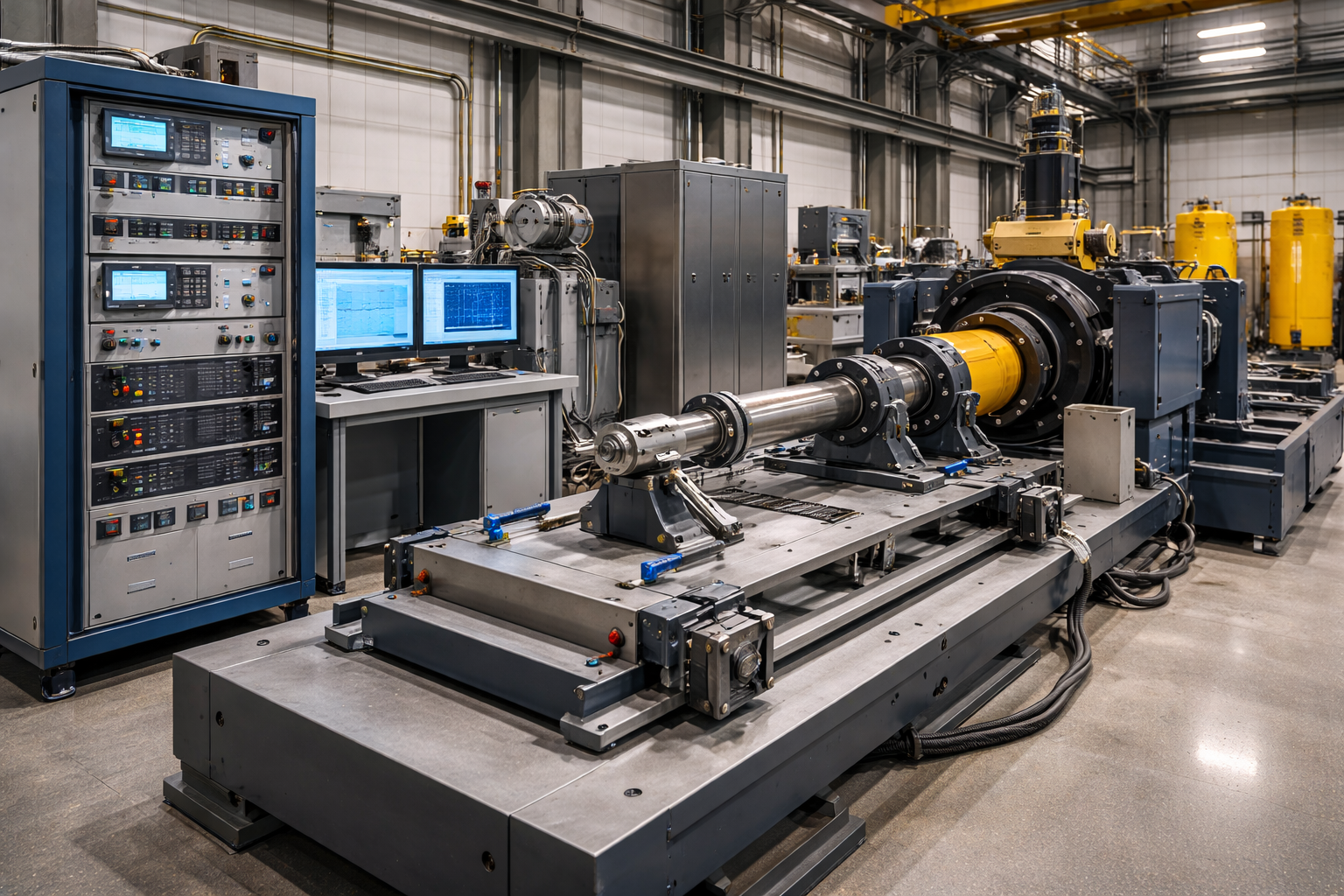

Dedicated dynamic test facilities enable precise control of load inputs and allow identical test conditions to be applied repeatedly. This transforms testing from a qualitative check into a quantitative validation process.

Applications Requiring Dynamic Shock Testing

Dynamic snubber and shock arrestor testing is commonly required in piping systems subject to pressure transients, industrial machinery protection systems, power and process plants, and aerospace or defense ground installations.

In these environments, inadequate performance during a transient event can result in extended downtime, equipment damage, or safety risks that far exceed the cost of proper validation.

Testing as a Risk Mitigation Strategy

Dynamic testing shifts failure discovery from operational environments into controlled test conditions. Identifying limitations during validation reduces uncertainty during commissioning, minimizes unplanned maintenance, and improves confidence in system behavior under abnormal operating scenarios.

Rather than reacting to failures, organizations can make informed design and selection decisions before systems are deployed.

Conclusion

Snubbers and shock arrestors are installed to manage unexpected, high-energy events. Evaluating them only under static conditions does not reflect the environments they are meant to protect against.

Dynamic testing provides critical insight into real-world performance and is an essential part of validating protective components used in safety- and reliability-critical systems.

Related Test Facility

For applications requiring controlled dynamic testing of snubbers and shock arrestors under transient load conditions, see the Dynamic Snubber / Shock Arrestor Test Facility by Neometrix Defence Limited:

https://neometrixgroup.com/products/dynamic-snubber-shock-arrestor-test-facility