Introduction

Modern rotating machinery operates at increasingly higher speeds and power densities. From aerospace engines and turbo-machinery to compressors, motors, and defence systems, rotor stability plays a decisive role in safety, reliability, and service life.

Uncontrolled vibration, resonance, or instability in rotating systems can lead to catastrophic failures. For this reason, rotor dynamics testing is a critical engineering activity performed during development, validation, and qualification of high-speed rotating equipment.

A dedicated Rotor Dynamics Test Facility enables engineers to evaluate real dynamic behavior under controlled and repeatable conditions.

What Is Rotor Dynamics?

Rotor dynamics is the study of the dynamic behavior of rotating shafts and assemblies under operational conditions. It focuses on how rotors respond to:

-

Rotational speed changes

-

Mass imbalance

-

Bearing and support stiffness

-

Damping characteristics

-

Thermal and mechanical loads

Understanding rotor dynamics is essential to prevent vibration-related failures and to ensure stable operation across the entire speed range.

Why Rotor Dynamics Testing Is Essential

Analytical simulations alone are not sufficient for high-speed rotating machinery. Physical testing is required to:

-

Identify critical speeds and resonance zones

-

Validate vibration amplitudes and phase response

-

Evaluate stability margins

-

Verify bearing and support system behavior

-

Detect potential instability before field operation

Without proper testing, issues may only surface during actual operation—often with severe consequences.

Limitations of Conventional Testing Methods

Standard test setups or operational trials often fail to capture true rotor dynamic behavior because they:

-

Do not allow controlled speed ramp-up through critical speeds

-

Lack precise vibration and displacement measurement

-

Cannot safely simulate instability conditions

-

Are unsuitable for experimental validation

This is why specialized rotor dynamics test facilities are required for advanced rotating systems.

What Is a Rotor Dynamics Test Facility?

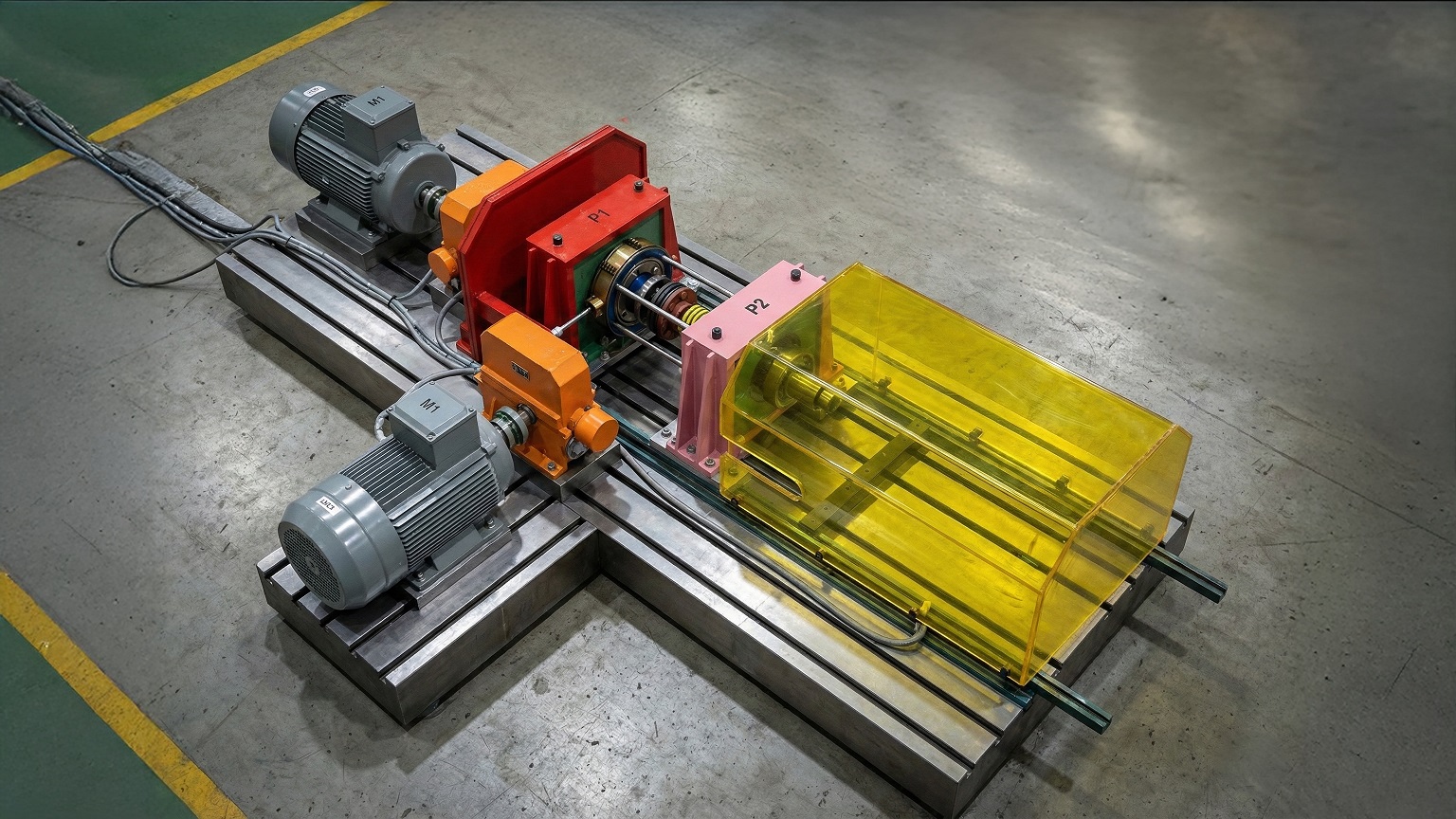

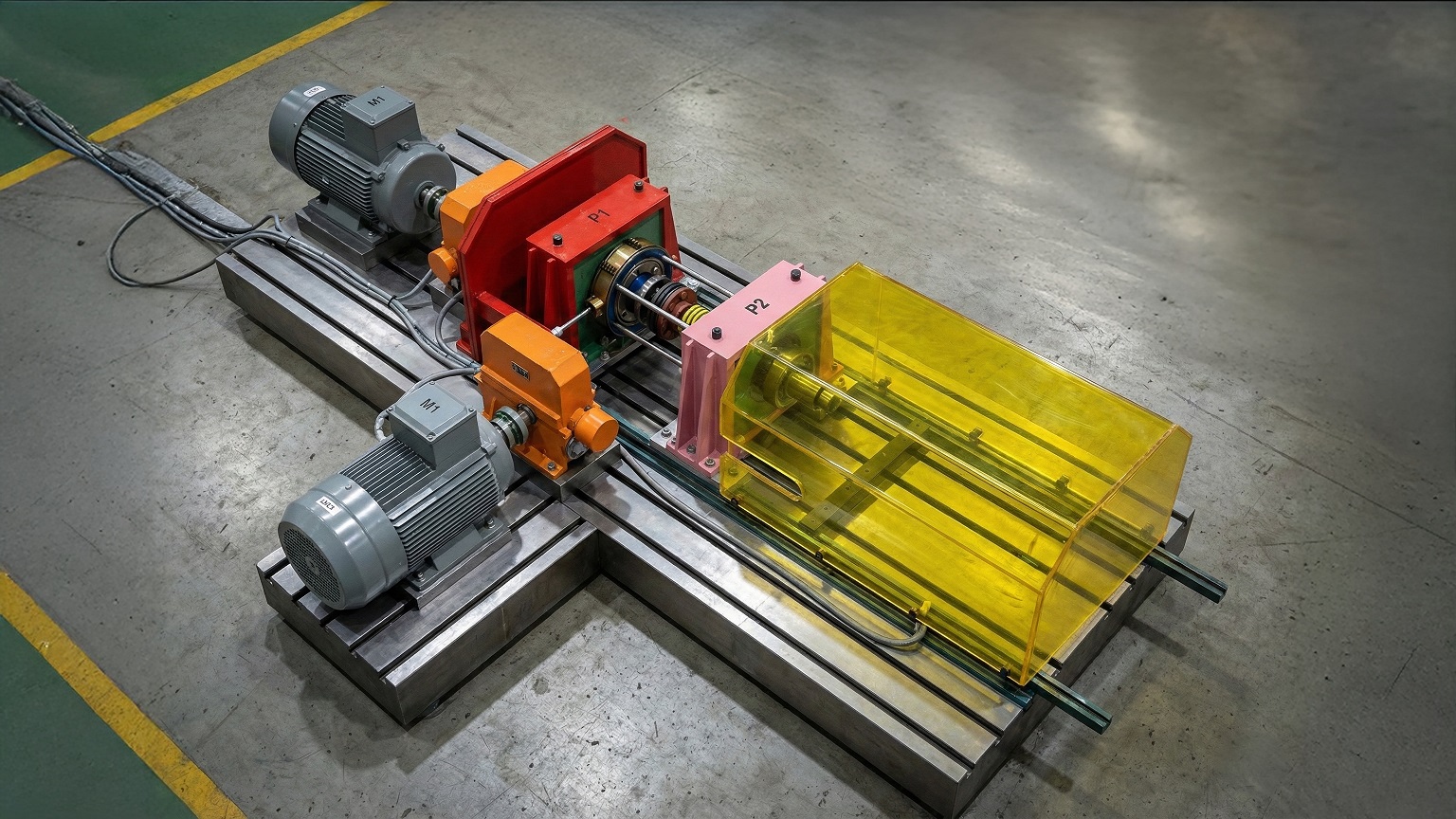

A Rotor Dynamics Test Facility is a specialized testing system designed to experimentally evaluate the dynamic behavior of rotating shafts and assemblies over a wide speed range.

A purpose-built

👉 Rotor Dynamics Test Facility

https://neometrixgroup.com/products/rotor-dynamics-test-facility

allows engineers to safely investigate vibration characteristics, critical speeds, damping, and stability limits under controlled laboratory conditions.

Key Parameters Evaluated in Rotor Dynamics Testing

Rotor dynamics test facilities are used to measure and analyze:

-

Critical speeds and mode shapes

-

Shaft vibration amplitude and phase

-

Rotor imbalance response

-

Bearing stiffness and damping effects

-

Stability thresholds and whirl behavior

-

Dynamic response during run-up and coast-down

These measurements form the basis for design validation and performance optimization.

Engineering Challenges in High-Speed Rotating Systems

High-speed rotors present unique engineering challenges, including:

-

Passage through multiple critical speeds

-

Thermal growth and alignment changes

-

Nonlinear bearing behavior

-

Cross-coupled stiffness effects

-

Potential for self-excited vibrations

Rotor dynamics testing helps engineers understand and mitigate these risks before deployment.

Applications of Rotor Dynamics Test Facilities

Rotor dynamics test facilities are widely used in:

-

Aerospace engines and turbo-machinery

-

Defence propulsion and rotating subsystems

-

Compressors and pumps

-

Electric motors and generators

-

Research and academic laboratories

In these applications, rotor dynamic validation is a mandatory step for safety and reliability.

Instrumentation and Control in Modern Test Facilities

Advanced rotor dynamics test facilities incorporate:

-

Precision vibration and displacement sensors

-

High-speed data acquisition systems

-

Controlled speed ramp-up and coast-down

-

Real-time monitoring and analysis

-

Robust safety and containment systems

Automation ensures repeatability, accuracy, and safe operation across all test conditions.

Custom Rotor Dynamics Test Solutions by Neometrix Group

Neometrix Group designs and manufactures custom rotor dynamics test facilities tailored to specific rotor sizes, speed ranges, bearing configurations, and test objectives.

Each system is engineered with a focus on:

-

Accurate dynamic characterization

-

Safe operation at high rotational speeds

-

Flexibility for research and qualification testing

-

Compliance with aerospace and defence requirements

👉 View product details:

Rotor Dynamics Test Facility

https://neometrixgroup.com/products/rotor-dynamics-test-facility

Read This Article on Medium

This engineering article is also available on Medium for wider technical discussion and reach:

Conclusion

Rotor dynamics testing is a fundamental requirement for the development and validation of high-speed rotating machinery. By experimentally evaluating vibration behavior, critical speeds, and stability margins, engineers can ensure safe, reliable, and efficient operation.

For aerospace, defence, and high-performance industrial systems, a dedicated rotor dynamics test facility is indispensable.