Starter Generator Testing

Why Comprehensive Validation Is Critical for Aerospace and Defence Power Systems

Introduction

Starter generators play a dual and critical role in modern aerospace and defence platforms. They function as starters during engine start-up and as generators during normal operation, supplying electrical power to onboard systems.

Because starter generators operate across wide speed, torque, and electrical load ranges, any performance deviation can directly affect engine start reliability, power quality, and overall system safety. This makes dedicated starter generator testing an essential part of development, qualification, and maintenance.

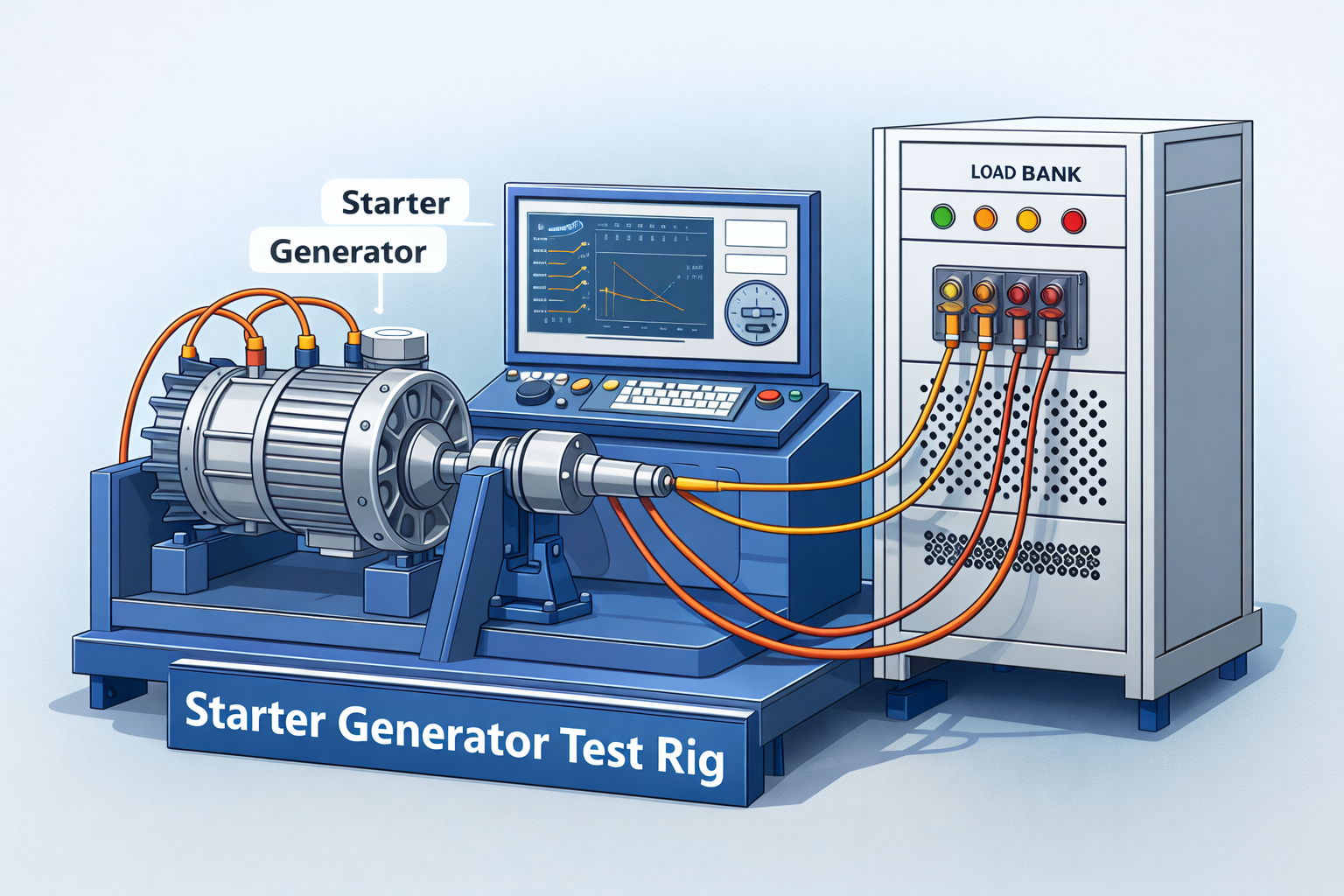

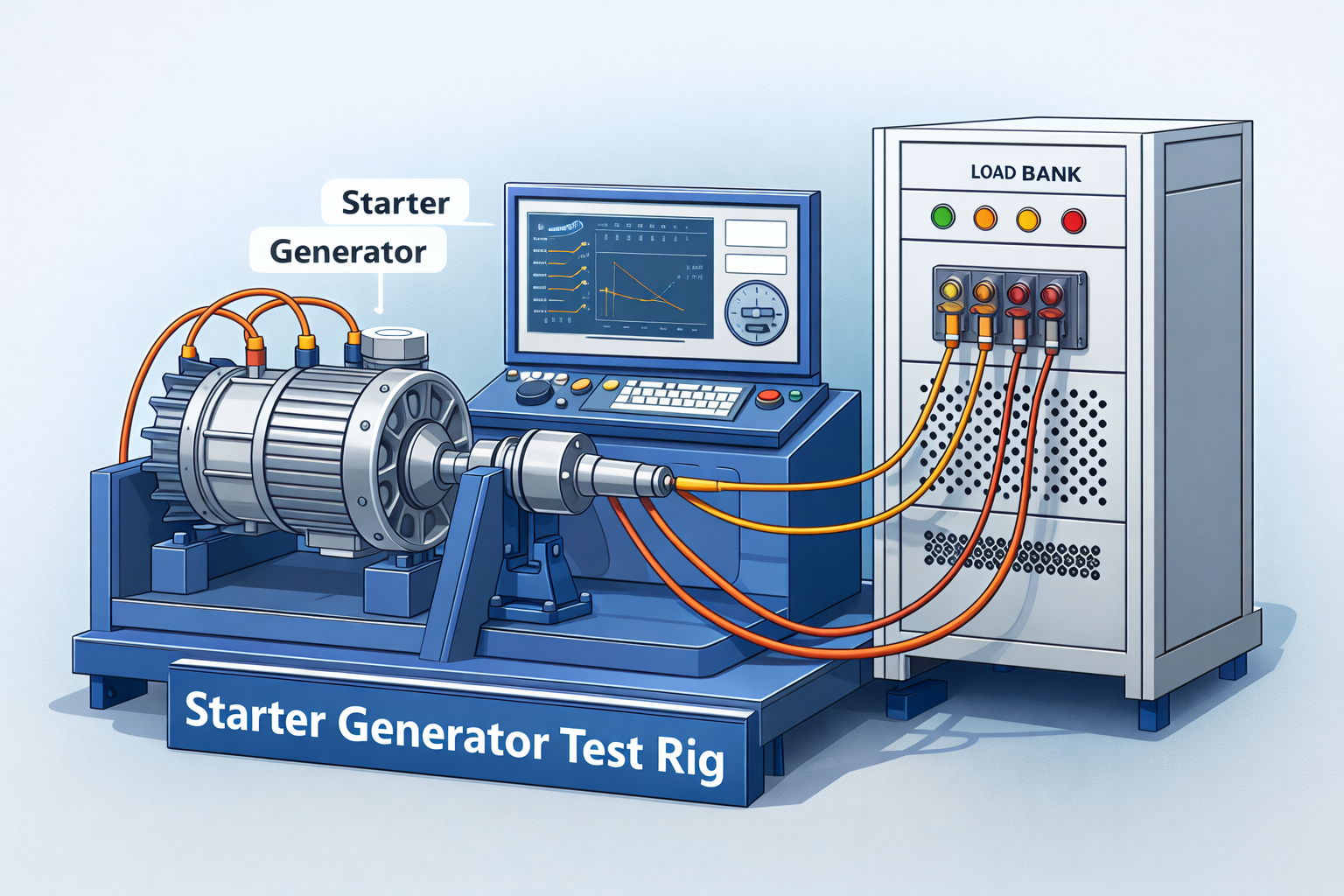

A purpose-built Starter Generator Test Rig allows engineers to validate these machines under realistic and repeatable operating conditions.

What Is a Starter Generator?

A starter generator is an electromechanical unit that combines two functions:

-

Starter mode: provides high starting torque to initiate engine rotation

-

Generator mode: supplies electrical power once the engine is running

This dual-function operation subjects the unit to:

-

High transient currents

-

Rapid torque changes

-

Wide speed ranges

-

Thermal and electrical stress

Testing must therefore cover both mechanical and electrical performance across all operating modes.

Why Starter Generator Testing Is Essential

Testing is required to ensure that starter generators meet stringent aerospace and defence requirements, including:

-

Reliable engine start under varying conditions

-

Stable power generation across speed ranges

-

Electrical performance under load variations

-

Thermal behavior during prolonged operation

-

Compliance with qualification and acceptance standards

Without comprehensive testing, failures may only appear during operational deployment—where corrective action is extremely costly.

Limitations of Conventional Testing Approaches

Generic electrical or mechanical test setups are often insufficient because they:

-

Cannot accurately simulate combined starter and generator modes

-

Do not replicate real speed–torque profiles

-

Lack precise load control and measurement

-

Provide limited data for fault diagnosis

This is why dedicated starter generator test rigs are used for aerospace and defence programs.

What Is a Starter Generator Test Rig?

A Starter Generator Test Rig is a specialized system designed to simulate real operating conditions and evaluate starter generator performance in both starter and generator modes.

A purpose-built

👉 Starter Generator Test Rig

https://neometrixgroup.com/products/starter-generator-test-rig

enables controlled testing of mechanical, electrical, and thermal parameters while ensuring operator safety and measurement accuracy.

Key Parameters Evaluated During Testing

Starter generator test rigs are used to measure and analyze:

-

Starting torque and current draw

-

Speed–torque characteristics

-

Generated voltage, current, and power output

-

Efficiency across operating modes

-

Thermal rise and cooling effectiveness

-

Fault conditions and protection response

These parameters are critical for qualification, acceptance testing, and performance optimization.

Engineering Challenges in Starter Generator Testing

Testing starter generators involves several technical challenges, such as:

-

Handling high transient electrical loads

-

Managing heat generation during start cycles

-

Accurately simulating engine inertia

-

Switching seamlessly between operating modes

-

Ensuring safe operation under fault conditions

Dedicated test rigs are engineered to address these challenges through advanced control systems and robust mechanical design.

Applications of Starter Generator Test Rigs

Starter generator test rigs are widely used in:

-

Aircraft engine development and maintenance

-

Defence aviation platforms

-

Unmanned aerial systems (UAS)

-

Aerospace manufacturing and MRO facilities

-

Research and qualification laboratories

In these applications, testing is a mandatory requirement for reliability and safety.

Instrumentation and Automation in Modern Test Rigs

Modern starter generator test rigs integrate:

-

Precision torque, speed, and electrical sensors

-

Programmable load banks

-

Automated test sequencing

-

Real-time data acquisition and reporting

-

Safety interlocks and protection systems

Automation ensures repeatable testing, accurate results, and reduced operator dependency.

Custom Starter Generator Test Solutions by Neometrix Group

Neometrix Group designs and manufactures custom starter generator test rigs tailored to specific power ratings, speed ranges, electrical configurations, and aerospace standards.

Each system is engineered with a focus on:

-

Accurate performance validation

-

Safety under high electrical and mechanical loads

-

Flexibility for development and production testing

-

Compliance with aerospace and defence requirements

👉 View product details:

Starter Generator Test Rig

https://neometrixgroup.com/products/starter-generator-test-rig

Read This Article on Medium

This engineering article is also available on Medium for wider technical discussion and reach:

Conclusion

Starter generator testing is essential to ensure reliable engine start, stable power generation, and long-term system performance in aerospace and defence platforms. A dedicated starter generator test rig enables comprehensive validation under realistic operating conditions.

For flight-critical and mission-critical systems, professional starter generator testing is not optional—it is essential.