Hydraulic Suspension Units (HSUs) are a key part of modern vehicle and platform design, particularly in defense vehicles, rail systems, heavy machinery, and specialized industrial applications. By managing load distribution, damping, and dynamic response, HSUs directly influence ride comfort, stability, and operational safety.

Because these units operate under high loads and continuously changing conditions, reliable testing of HSUs is not optional — it is essential.

Understanding the Complexity of Hydraulic Suspension Units

Unlike simple hydraulic actuators, HSUs combine multiple functional elements into a single assembly. These typically include:

-

Hydraulic cylinders

-

Accumulators and damping elements

-

Control valves and internal flow paths

-

Mechanical linkages and seals

During real operation, HSUs are exposed to fluctuating loads, pressure spikes, temperature variations, and repeated dynamic cycles. Small internal issues that go undetected during basic checks can evolve into performance degradation or failure over time.

Why Conventional Testing Is Often Insufficient

Traditional inspection and component-level testing methods can verify individual elements, but they often fail to reveal how the suspension unit behaves as a complete system.

Common issues that may be missed include:

-

Inconsistent damping characteristics under dynamic load

-

Pressure decay caused by internal leakage

-

Non-linear response during compression and rebound cycles

-

Degradation in performance over extended duty cycles

These behaviors typically emerge only when the HSU is tested under realistic operating conditions.

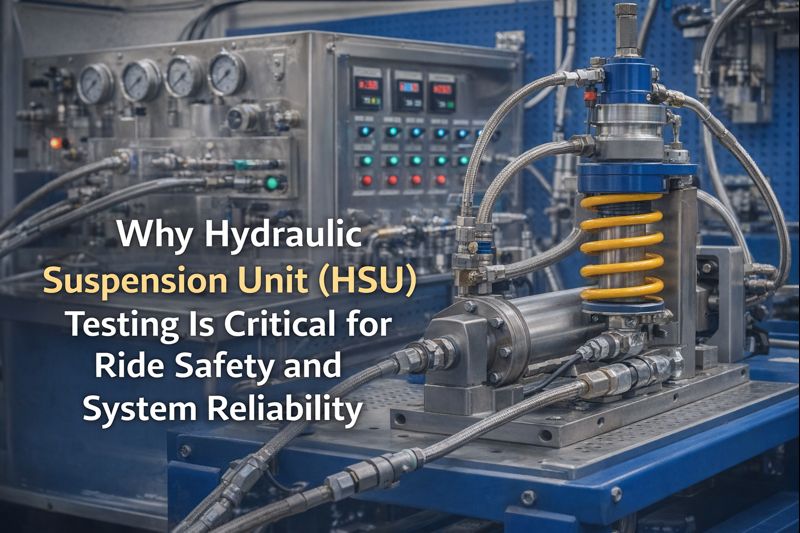

Role of a Dedicated HSU Test Bench

A Hydraulic Suspension Unit Test Bench enables engineers and maintenance teams to test the suspension unit as an integrated system rather than as isolated components.

Such a test bench allows for:

-

Controlled application of load, pressure, and displacement

-

Measurement of force, stroke, pressure, and response time

-

Dynamic cycling to simulate real operating conditions

-

Endurance testing to evaluate long-term performance

-

Identification of leakage, hysteresis, and damping inconsistencies

By recreating operational scenarios in a controlled environment, system-level issues can be identified early and reliably.

Importance in Safety-Critical Applications

HSUs are widely used in platforms where safety, stability, and durability are critical. These include:

-

Defense vehicles operating on varied terrain

-

Rail suspension systems

-

Heavy-duty industrial and off-road machinery

-

Specialized transport and support platforms

In such applications, suspension failure or degraded performance can lead to reduced control, increased wear, or safety risks. Bench-based testing significantly reduces these risks by validating performance before deployment or reuse.

Industry Shift Toward System-Level Validation

OEMs and MRO facilities are increasingly adopting dedicated HSU test benches during:

-

New product development and qualification

-

Production acceptance testing

-

Maintenance and overhaul validation

-

Failure analysis and performance benchmarking

This shift reflects a broader industry trend toward predictive, data-driven validation rather than reactive troubleshooting.

Further Reading and Practical Reference

Neometrix regularly publishes engineering resources that explore real-world testing challenges and validation strategies for hydraulic systems.

A detailed engineering resource on Hydraulic Suspension Unit testing is available here:

🔗 https://medium.com/@robinyadav8180/why-hydraulic-suspension-unit-hsu-testing-is-critical-for-ride-safety-and-system-reliability-ae7bc2f23942

For readers interested in practical implementation, a reference to Hydraulic Suspension Unit Test Bench solutions can be found here:

🔗 https://neometrixgroup.com/products/hydraulic-suspension-unit-test-bench-manufacturer