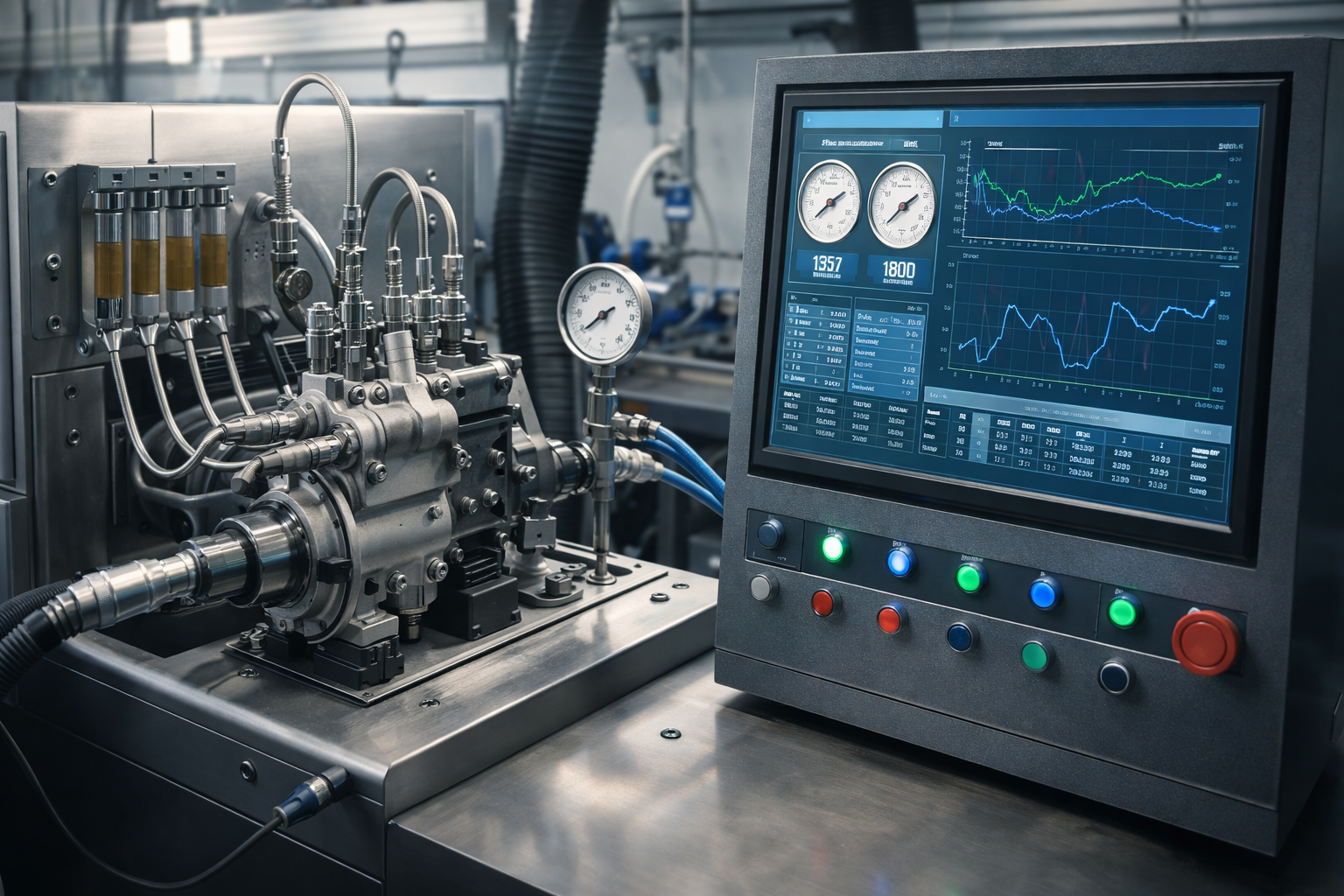

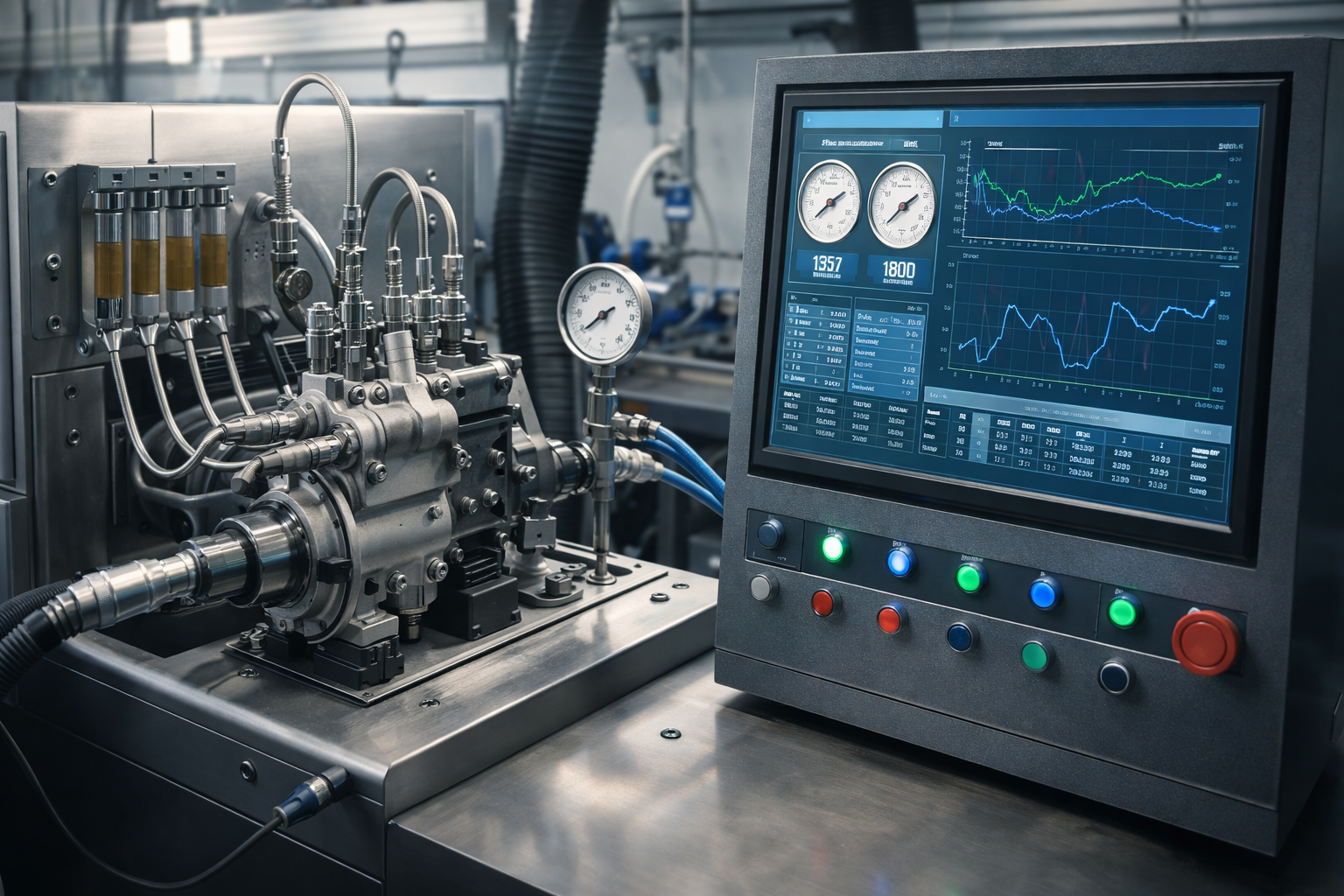

Fuel injection pumps play a critical role in engine performance, efficiency, and emissions control. Even minor deviations in pressure, timing, or fuel delivery can lead to power loss, excessive fuel consumption, smoke generation, or long-term engine damage. This is why accurate testing and calibration of fuel injection pumps is essential across manufacturing, maintenance, and overhaul operations.

Understanding Fuel Injection Pump Testing

Fuel injection pump testing involves simulating real engine operating conditions to verify how accurately a pump delivers fuel at different speeds, loads, and pressures. A dedicated test bench allows engineers and technicians to measure key parameters such as:

-

Fuel delivery volume and consistency

-

Injection pressure characteristics

-

Pump timing accuracy

-

Response under varying RPM conditions

-

Leakage and internal wear indicators

By recreating controlled test conditions, faults that are difficult to detect on an installed engine can be identified early.

Importance in Manufacturing and Overhaul Facilities

In manufacturing environments, fuel injection pump test benches ensure quality assurance before pumps are dispatched for engine assembly. Each unit can be calibrated to meet exact performance specifications, reducing field failures and warranty claims.

In maintenance and overhaul workshops, these systems are equally valuable. Worn components, internal leakages, or calibration drift can be detected quickly, enabling precise repair rather than guesswork-based servicing. This leads to improved engine reliability and extended service life.

Supporting Emissions and Fuel Efficiency Goals

As emission regulations become more stringent, accurate fuel metering has never been more important. Properly tested and calibrated injection pumps contribute directly to:

-

Lower exhaust emissions

-

Improved combustion efficiency

-

Reduced fuel consumption

-

Consistent engine output across operating ranges

Test benches therefore play a key role in helping industries meet environmental and regulatory requirements.

Modern Test Benches: Built for Accuracy and Repeatability

Advanced fuel injection pump test benches are designed for repeatable, high-precision testing. With robust mechanical construction, precise measurement instrumentation, and flexible configuration options, they support a wide range of pump types used in automotive, industrial, marine, and power-generation applications.

For a detailed look at a modern Fuel Injection Pump Test Bench and its capabilities, visit:

🔗 https://neometrixgroup.com/products/fuel-injection-pump-test-bench