Hydraulic systems are only as reliable as their control valves. These components regulate pressure, flow, and direction—making them the decision-makers of any hydraulic circuit. A minor deviation in valve behavior can cascade into efficiency losses, unstable motion, overheating, or even catastrophic system failure.

This is why systematic testing of hydraulic control valves has become a cornerstone of modern industrial quality assurance.

The Critical Role of Control Valves in Hydraulic Systems

Control valves are exposed to:

-

High pressure differentials

-

Rapid switching cycles

-

Contaminated fluids

-

Thermal fluctuations

Over time, these stresses can affect response time, sealing integrity, and flow characteristics. Without proper validation, even a precision-machined valve can behave unpredictably once installed in a real system.

Testing ensures the valve performs as designed, not just as manufactured.

Why Functional Testing Matters More Than Visual Inspection

Visual checks and dimensional inspection confirm manufacturing quality—but they cannot predict operational behavior. Functional testing evaluates how a valve actually performs under simulated working conditions, including:

-

Pressure holding capability

-

Flow vs. pressure characteristics

-

Leakage across ports

-

Dynamic response to actuation

These parameters directly impact system stability and efficiency, especially in high-duty-cycle applications.

Challenges in Hydraulic Valve Performance Evaluation

Testing hydraulic control valves is not trivial. Engineers face several challenges:

1. Accurate Pressure & Flow Control

Small variations can significantly alter test results, demanding precise regulation and measurement.

2. Repeatability

Industrial QA requires consistent results across batches, shifts, and test cycles.

3. Operator Safety

Testing involves pressurized fluids that can store substantial energy, making controlled test environments essential.

4. Data Traceability

Modern manufacturing increasingly demands documented proof of performance—not just pass/fail decisions.

These challenges have driven the adoption of dedicated hydraulic valve test benches over improvised test setups.

Standardization and Compliance Pressures

Industries such as power generation, mobile hydraulics, process plants, and heavy machinery operate under strict internal and regulatory standards. Consistent valve testing supports:

-

Reduced warranty claims

-

Predictable system behavior

-

Easier fault diagnosis in the field

-

Compliance with customer and regulatory requirements

In many organizations, valve testing is now integrated directly into production and maintenance workflows.

From Maintenance to Predictive Reliability

Beyond manufacturing QA, valve testing plays a role in predictive maintenance. Periodic performance evaluation helps identify:

-

Wear-related leakage trends

-

Sluggish response due to contamination

-

Degradation before functional failure

This approach reduces unplanned downtime and improves lifecycle management of hydraulic assets.

Conclusion

Hydraulic control valves may be compact, but their impact on system performance is enormous. Reliable testing bridges the gap between theoretical design and real-world operation—ensuring systems behave safely, efficiently, and predictably.

As hydraulic applications grow more demanding, investing in structured valve testing is no longer optional—it is fundamental to system reliability.

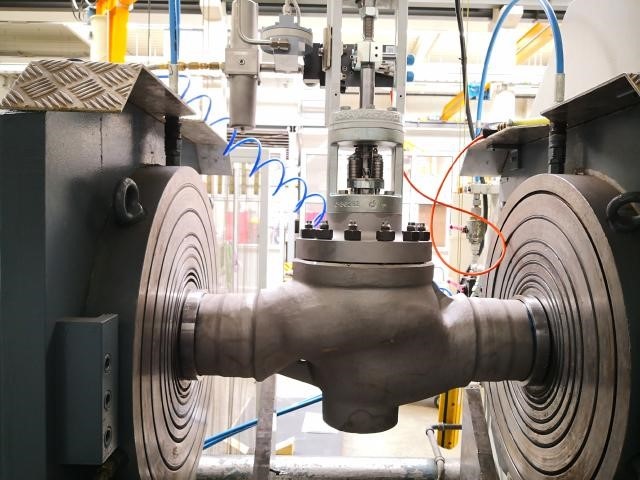

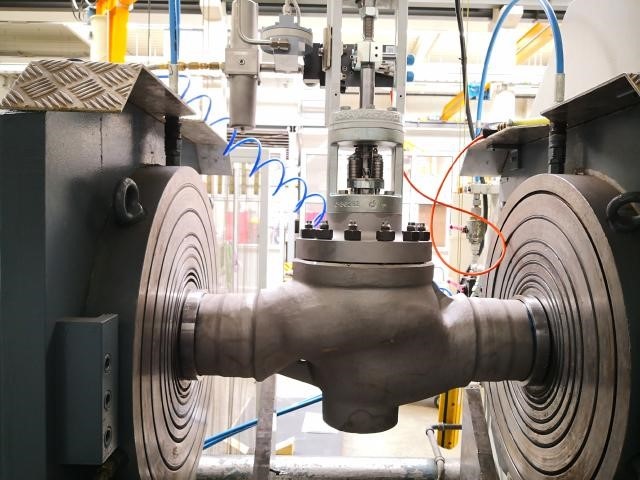

To explore how structured hydraulic valve testing is implemented in a dedicated solution, see Neometrix Group’s

👉 Hydraulic Control Valve Test Bench

🔗 https://neometrixgroup.com/products/hydraulic-control-valve-test-bench