Hydraulic hoses are critical components in fluid power systems, yet they are often underestimated during system validation. In real operating environments, hoses are exposed to pressure cycling, pulsations, vibration, temperature variation, and long service durations, all of which contribute to gradual degradation and eventual failure.

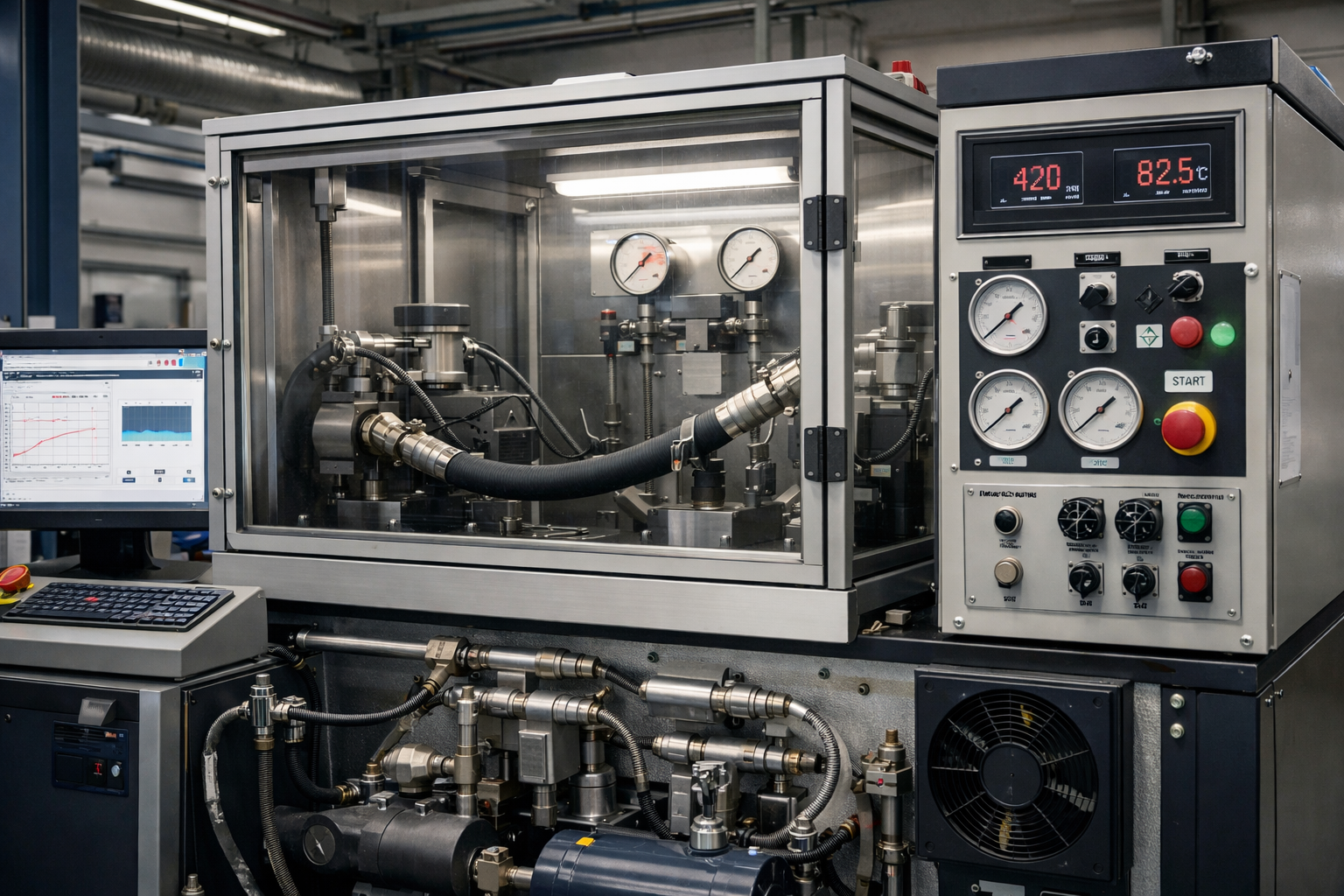

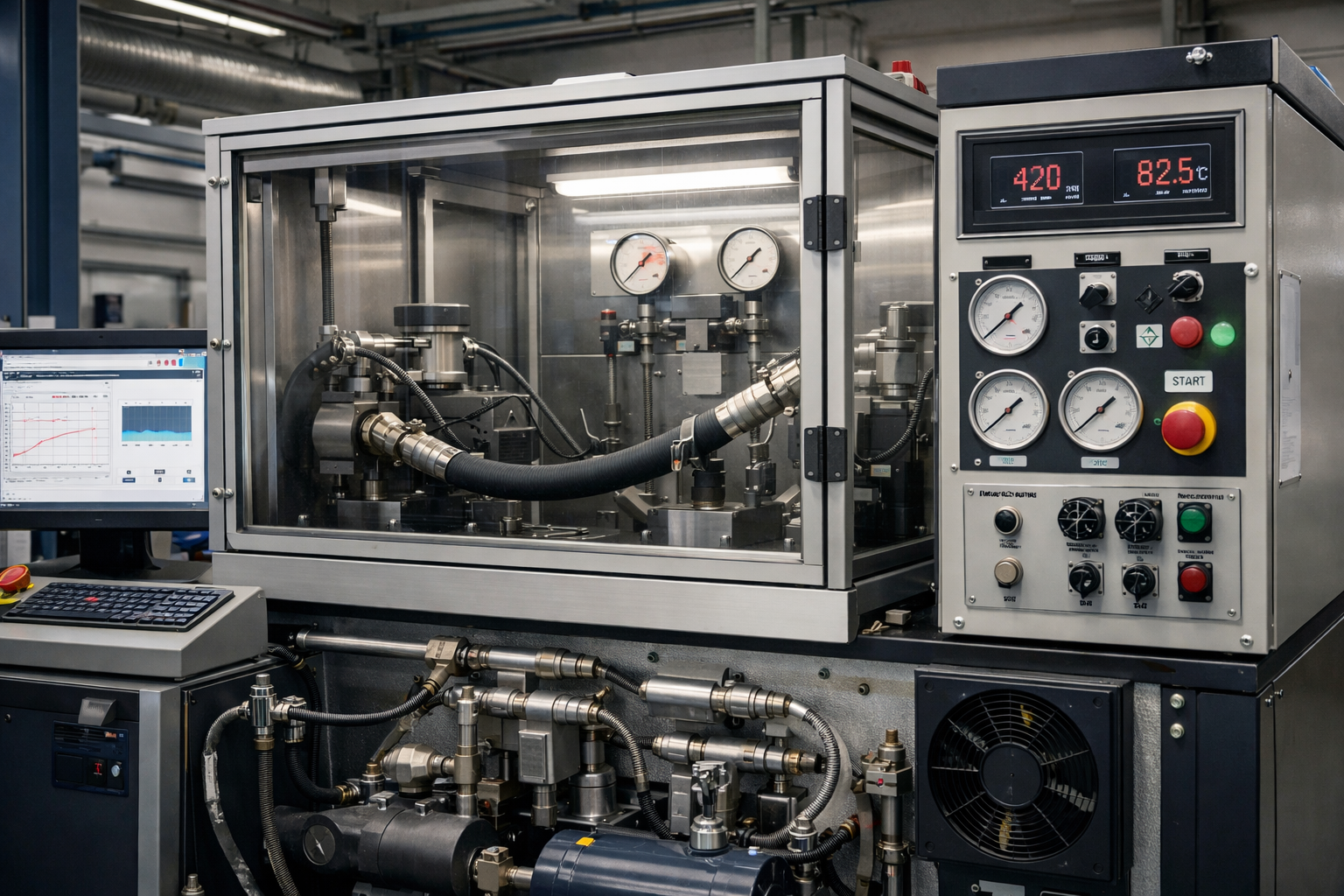

A Hose Test Bench is designed to evaluate hose performance under these realistic conditions, helping engineers understand durability, fatigue behavior, and failure mechanisms before hoses are deployed in the field.

Why Hydraulic Hose Testing Is Necessary

Unlike rigid pipes, hoses combine flexible materials, reinforcement layers, and crimped fittings. This makes their behavior under load more complex and more sensitive to cyclic stress.

Common causes of hose failure include:

-

Pressure impulse fatigue

-

Reinforcement layer breakdown

-

Leakage at crimped fittings

-

Material aging due to temperature and fluid compatibility

Many of these issues do not appear during simple static pressure tests and only become evident after repeated pressure cycling.

What Is a Hose Test Bench?

A hose test bench is a controlled testing system used to apply pressure, pressure impulses, and endurance cycles to hydraulic hoses. The objective is not only to verify maximum pressure capability, but also to assess long-term performance under realistic operating conditions.

Typical tests performed on a hose test bench include:

-

Proof pressure testing

-

Burst pressure testing

-

Pressure impulse and cyclic endurance testing

-

Leak monitoring during operation

These tests provide insight into how hoses behave over time rather than at a single load point.

Limitations of Static Pressure Testing

Static pressure tests confirm that a hose can withstand a specified pressure for a short duration. While necessary, they do not represent real service conditions where pressure fluctuates continuously.

Most in-service hose failures occur due to:

-

Accumulated fatigue from cyclic loading

-

Local stress concentration near fittings

-

Progressive weakening of reinforcement layers

Endurance and impulse testing are required to reveal these failure modes.

Applications of Hose Test Benches

Aerospace and Defense

Hydraulic hoses in aerospace and defense systems are subject to frequent pressure changes and strict reliability requirements. Endurance testing supports qualification and safety validation.

Industrial and Mobile Hydraulics

Manufacturing equipment, construction machinery, and mobile systems rely on hoses that operate continuously under varying loads.

Research and Product Development

Hose manufacturers and system designers use test benches to compare designs, materials, and crimping methods.

Quality Assurance

Hose test benches help verify consistency between production batches and detect deviations before field installation.

Modern Hose Testing Systems

Modern hose test benches typically integrate:

-

Servo-controlled pressure generation

-

Automated cycle counting and data logging

-

Continuous monitoring of pressure and leakage

-

Safety interlocks and protective enclosures

Solutions developed by organizations such as Neometrix Group are often configured to replicate actual duty cycles, enabling more representative testing outcomes.

🔗 Related system:

https://neometrixgroup.com/products/hose-test-bench

Conclusion

Hydraulic hose reliability depends not only on strength, but on how well a hose withstands repeated pressure cycles and long-term operating conditions. A hose test bench provides engineers with the data needed to understand fatigue behavior, validate designs, and reduce the risk of in-service failures.

By simulating real-world operating stress in a controlled environment, hose testing becomes a key part of building safer and more reliable hydraulic systems.