Introduction

Aerospace bearings operate under some of the most extreme conditions in engineering.

Very high rotational speeds, tight tolerances, thermal stress, and continuous dynamic loads mean that even minor defects can lead to catastrophic failure.

For applications such as aircraft actuators, auxiliary power units (APUs), turbo-machinery, and flight control systems, bearings must be tested and validated at actual operating speeds—often reaching tens of thousands of revolutions per minute.

This is where high-speed aerospace bearing test benches, capable of reaching up to 70,000 RPM, become essential.

Why High-Speed Bearing Testing Matters in Aerospace

In aerospace systems, bearings are not just mechanical components—they are flight-critical elements.

Testing at real operating speeds is necessary to verify:

-

Mechanical stability at extreme RPM

-

Thermal behavior and heat dissipation

-

Lubrication effectiveness under centrifugal forces

-

Vibration and noise characteristics

-

Long-term durability and fatigue life

Bearings that perform well at low or moderate speeds may fail when subjected to actual aerospace operating conditions.

Limitations of Conventional Bearing Testing

Standard bearing test setups are often insufficient for aerospace validation because they:

-

Cannot reach required rotational speeds

-

Do not replicate real dynamic loading

-

Fail to simulate thermal buildup accurately

-

Lack precise vibration and condition monitoring

As a result, aerospace programs require dedicated high-speed test benches designed specifically for ultra-high RPM operation.

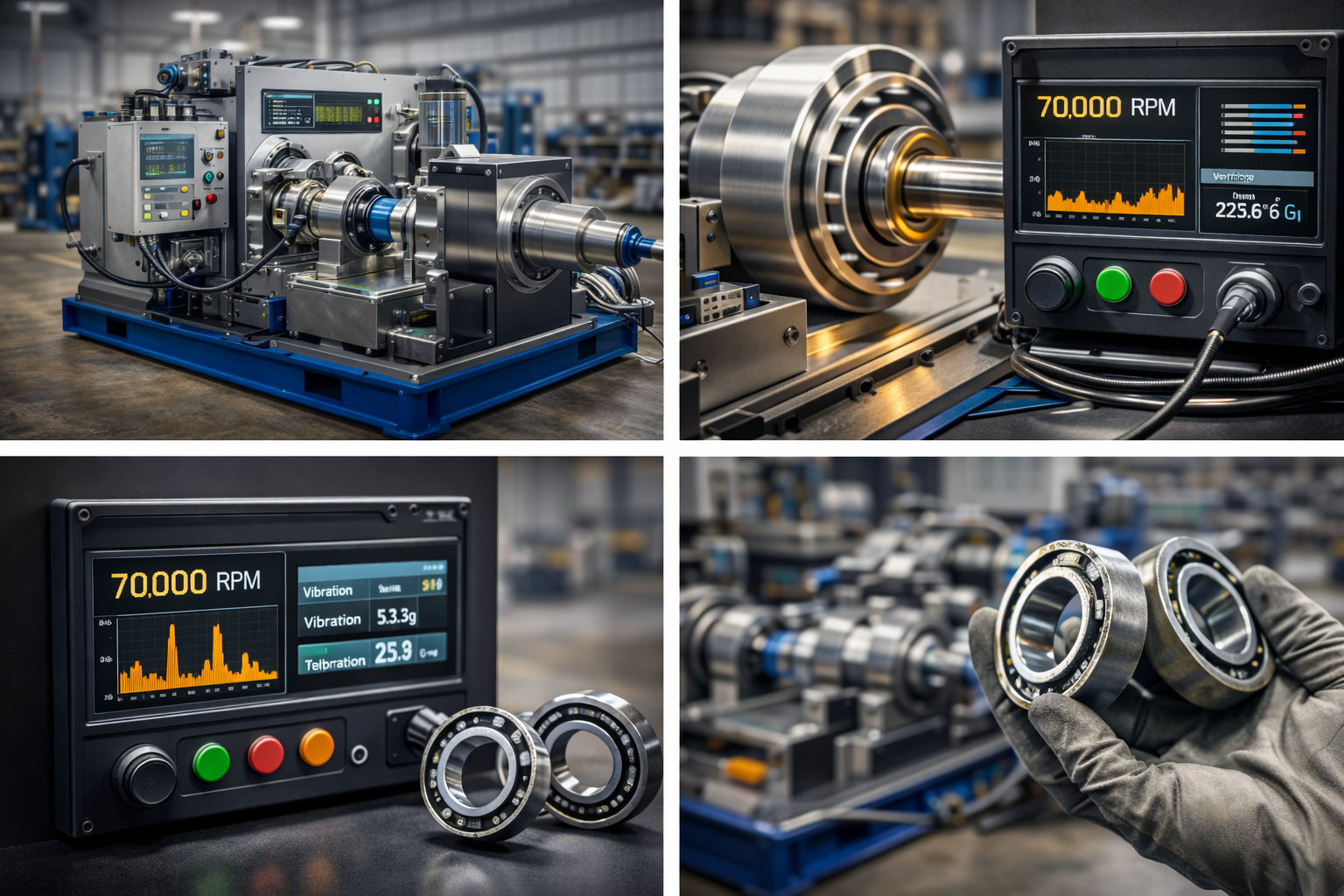

What Is a 70,000 RPM Aerospace Bearing Test Bench?

A 70,000 RPM aerospace bearing test bench is a specialized testing system designed to evaluate bearing performance under extreme rotational speeds while maintaining precise control and measurement.

A purpose-built

👉 70,000 RPM Aerospace Bearing Test Bench

https://neometrixgroup.com/products/70000-rpm-aerospace-bearing-test-bench

allows engineers to safely test bearings at operational limits while monitoring all critical parameters in real time.

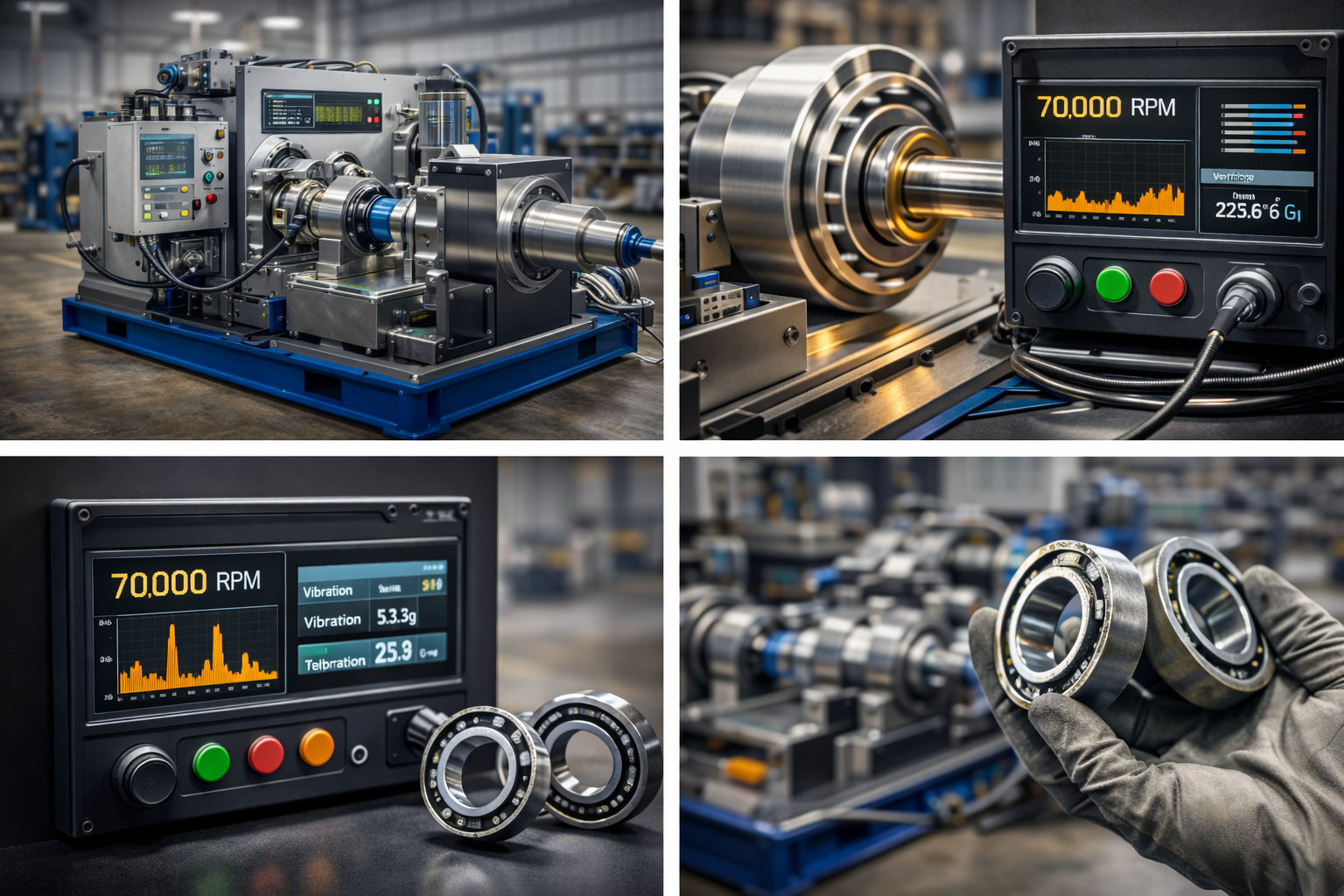

Key Parameters Evaluated During High-Speed Testing

Aerospace bearing test benches are used to evaluate:

-

Rotational speed stability up to 70,000 RPM

-

Temperature rise at bearing races and housings

-

Vibration and imbalance behavior

-

Lubrication performance at high centrifugal forces

-

Bearing wear and failure modes

-

Noise characteristics under load

Accurate measurement of these parameters is essential for qualification and certification.

Engineering Challenges at Ultra-High RPM

Testing bearings at very high speeds introduces unique engineering challenges:

-

Rotor dynamic stability

-

Heat generation and thermal expansion

-

Lubricant aeration and starvation

-

Precision balancing of rotating components

-

Safety containment for high-energy rotating parts

High-speed bearing test benches are engineered to address these challenges through robust mechanical design, advanced control systems, and comprehensive safety features.

Applications of High-Speed Aerospace Bearing Test Benches

Such test benches are used extensively in:

-

Aircraft actuator bearing validation

-

Auxiliary Power Unit (APU) components

-

Turbine and compressor bearings

-

Space and satellite mechanisms

-

Defence and military aerospace systems

In these applications, testing is not optional—it is a certification and reliability requirement.

Role of Automation and Instrumentation

Modern aerospace bearing test benches incorporate:

-

High-speed drive systems

-

Precision sensors for temperature, vibration, and speed

-

Automated test sequencing

-

Real-time data acquisition and logging

-

Safety interlocks and containment systems

Automation ensures repeatability, accuracy, and safe operation throughout the test cycle.

Custom Aerospace Bearing Test Solutions by Neometrix Group

Neometrix Group designs and manufactures custom high-speed aerospace bearing test benches tailored to specific bearing sizes, speed requirements, load conditions, and qualification standards.

Each system is engineered with a focus on:

-

Extreme-speed reliability

-

Measurement accuracy

-

Operator safety

-

Compliance with aerospace and defence requirements

👉 View product details:

70,000 RPM Aerospace Bearing Test Bench

https://neometrixgroup.com/products/70000-rpm-aerospace-bearing-test-bench

Read This Article on Medium

This engineering article is also available on Medium for wider technical discussion and reach:

Conclusion

High-speed bearing testing is a critical step in ensuring the safety, reliability, and performance of aerospace systems.

Testing at up to 70,000 RPM allows engineers to identify thermal, mechanical, and dynamic issues before components are deployed in flight-critical applications.

For aerospace programs where failure is not an option, dedicated high-speed bearing test benches are indispensable.