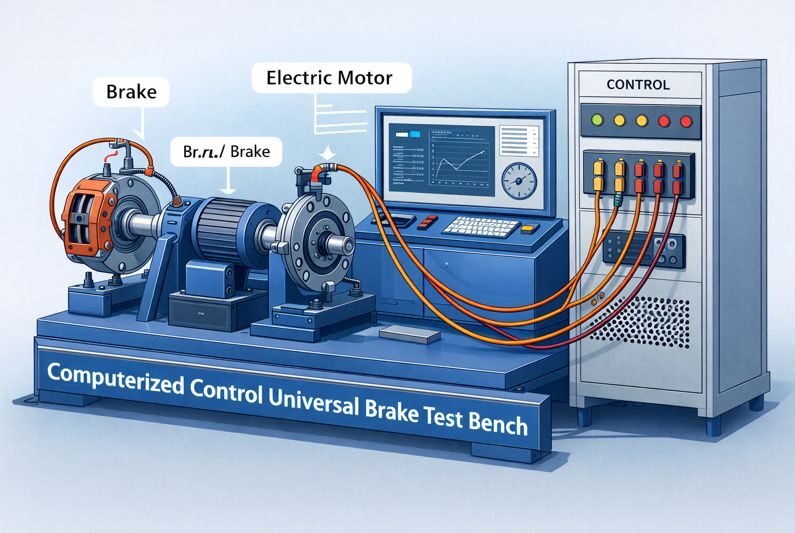

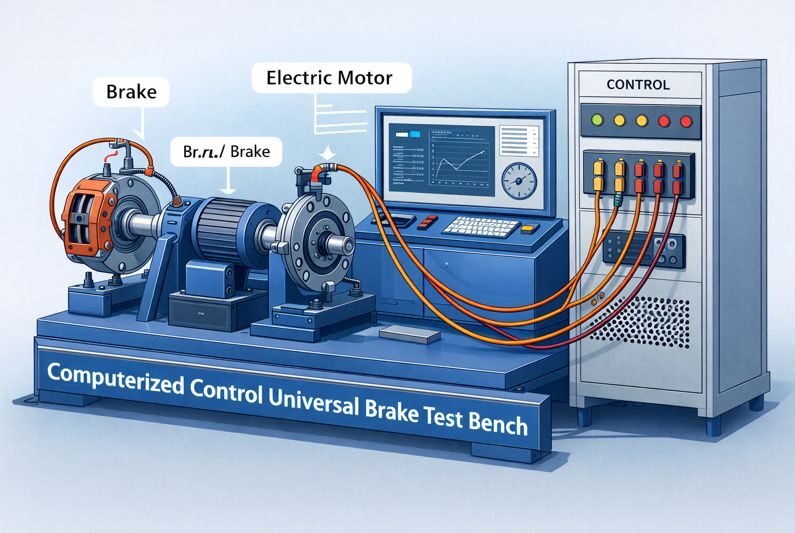

Why Computerized Brake Test Benches Are Essential for Safety-Critical Applications

Introduction

Brake systems are among the most safety-critical components in any mechanical system. Whether used in railways, automotive platforms, industrial machinery, or defence applications, brakes must perform reliably under varying loads, speeds, and environmental conditions.

Even minor inconsistencies in braking force, response time, or thermal behavior can lead to severe safety risks. This is why controlled, repeatable, and instrumented brake testing is a fundamental requirement during development, qualification, and production.

A Computerized Control Universal Brake Test Bench provides engineers with the ability to validate brake performance accurately under realistic operating conditions.

Why Brake System Testing Is Critical

Brake systems must be tested to ensure:

-

Consistent braking torque and force

-

Reliable response under dynamic load conditions

-

Stable performance across speed ranges

-

Thermal behavior during repeated braking cycles

-

Compliance with safety and industry standards

Testing under controlled conditions allows engineers to identify performance deviations long before brakes are deployed in real-world applications.

Limitations of Conventional Brake Testing Methods

Traditional or manual brake testing approaches often fall short because they:

-

Lack precise control of speed, load, and braking force

-

Provide limited data for performance analysis

-

Cannot repeat test cycles consistently

-

Are unsuitable for qualification and certification testing

As braking systems become more complex, computerized brake test benches have become essential.

What Is a Computerized Control Universal Brake Test Bench?

A Computerized Control Universal Brake Test Bench is a specialized testing system designed to evaluate the performance, durability, and safety of brake assemblies under controlled conditions.

A purpose-built

👉 Computerized Control Universal Brake Test Bench

https://neometrixgroup.com/products/computerized-control-universal-brake-test-bench

allows engineers to simulate real operating scenarios while accurately measuring braking force, torque, speed, temperature, and response characteristics.

Key Parameters Evaluated During Brake Testing

Universal brake test benches are used to measure and analyze:

-

Braking torque and force

-

Response time and stopping characteristics

-

Speed-dependent braking behavior

-

Thermal rise and heat dissipation

-

Fade and recovery performance

-

Wear and durability characteristics

These parameters are essential for design validation and safety assurance.

Engineering Challenges in Brake System Testing

Brake testing introduces several engineering challenges, such as:

-

Managing high thermal loads during repeated braking

-

Accurately simulating real inertia and speed profiles

-

Ensuring repeatability across test cycles

-

Monitoring performance degradation and wear

-

Maintaining operator safety during high-energy tests

Computerized control systems help address these challenges through precise automation and monitoring.

Applications of Universal Brake Test Benches

Computerized universal brake test benches are widely used in:

-

Railway and rolling stock brake systems

-

Automotive brake development and validation

-

Defence and military vehicle platforms

-

Industrial machinery braking systems

-

Research, qualification, and training laboratories

In these applications, brake testing is a mandatory safety requirement.

Instrumentation and Automation in Modern Brake Test Benches

Modern brake test benches integrate:

-

Precision sensors for torque, force, speed, and temperature

-

Computerized control and automation

-

Programmable test sequences

-

Real-time data acquisition and reporting

-

Safety interlocks and protection systems

Automation ensures consistent results, reduced operator dependency, and enhanced safety.

Custom Brake Test Solutions by Neometrix Group

Neometrix Group designs and manufactures computerized universal brake test benches tailored to specific brake types, load ranges, and industry standards.

Each system is engineered with a focus on:

-

Accurate performance measurement

-

Safety under high-energy testing conditions

-

Flexibility for multiple brake configurations

-

Compliance with industrial, automotive, rail, and defence requirements

👉 View product details:

Computerized Control Universal Brake Test Bench

https://neometrixgroup.com/products/computerized-control-universal-brake-test-bench

Read This Article on Medium

This engineering article is also available on Medium for wider technical discussion and reach:

Conclusion

Brake system testing is essential to ensure safety, reliability, and compliance in modern mechanical systems. A computerized universal brake test bench enables accurate, repeatable, and safe evaluation of braking performance under real-world conditions.

For applications where safety is non-negotiable, computerized brake testing is not optional—it is essential engineering practice.